Chillers

Liquid chillers quickly cool large amounts of liquid refrigerant in order to remove heat from the air or other liquids. They then pump cooled liquid or air out as needed.

Quick links to Chillers Information

A History of Chillers

Because chillers use the same basic technology as everyday air conditioners, the history of chiller technology starts with the history of air conditioning. In the 1800's, scientists like Benjamin Franklin first began experimenting with ways to use liquid refrigerant to cool liquids and air. These scientists discovered the principles of heat transfer, that they could lower the temperature of air using liquids such as water.

In 1902, Willis Carrier of New England created the first self-contained mechanical air conditioning system. He discovered that heating air reduces relative humidity allowing air to absorb moisture. Cooling the air then pulls heat and moisture from surroundings, reducing both humidity and ambient temperature in a room. This two-phase process of quick heat and quick underlies chilling technology to this day.

After Carrier's invention, research and development in chilling technology developed to meet growing demand. In 1931, scientists discovered that Freon had unique properties allowing it to cool more efficiently than water or air alone. In 1938, Trane introduced the refrigerant-based systems we see in modern-day chillers: compressor, condenser, and evaporator. This enclosed system allowed for the creation of industrial liquid chillers capable of cooling an enclosed space in a brief span of time. In 1950, the plastics industry started using industrial chillers to help meet the demand for quality plastics. This business decision allowed plastics to take center stage as the go-to material for everything from toys to bottling.

Toward the end of the 20th century, other industries began using chiller technology to increase production and improve quality. This would range from glass to power companies. Acting as a silent but necessary partner in the background, chiller technology helped provide the basis for the digital age by making the global electrical grid possible. Today, chillers form a necessary technology in a range of key industries.

Benefits of Using Chillers

While it may be possible to run some operations with or without liquid chillers, this machinery offers clear benefits.

Cooling Speed of Chillers

The main purpose of industrial chillers is to cool large amounts of material fast, and they do this better than any other type of equipment.

Space Saving of Chillers

Compared to other forms of cooling such as ice or chemicals like nitrogen, chillers take up less room and use that space more efficiently. Industrial chillers let businesses dedicate a set space for machinery. They keep things reliably cool, so that way owners can focus on the rest of their operations.

Predictable Cooling Temperature in Chillers

Where other cooling methods may cool some areas more than others, careful use of industrial chillers lets you keep temperatures even in a given area. Uneven temperatures could lead to product damage and product loss.

Chiller Cost Savings

Chillers can save money compared with alternate forms of keeping materials cool.

How Chillers Work

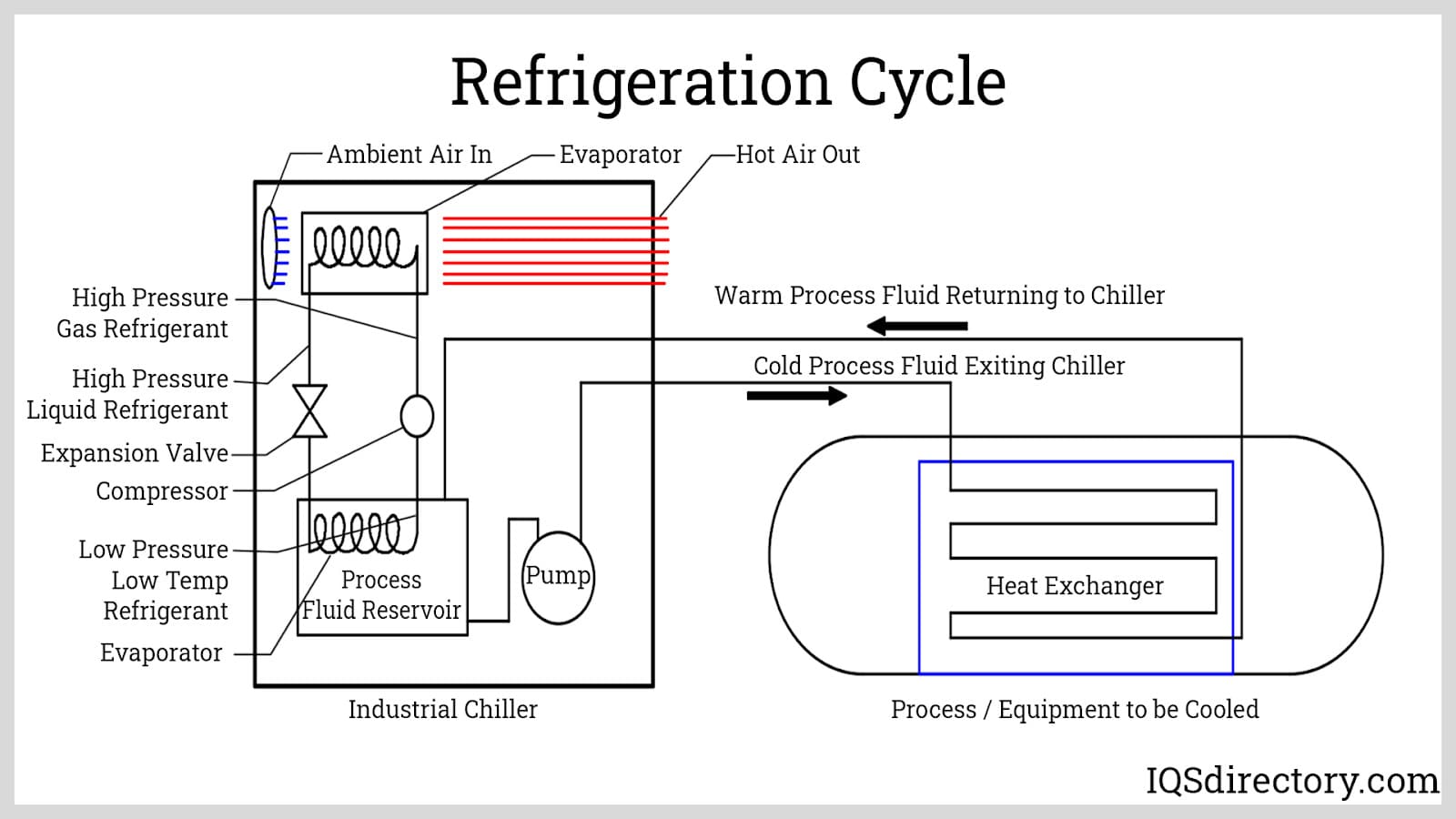

Modern liquid chillers use chemical reactions caused by liquid refrigerant moving through a repeated process of heat transfer. Refrigerant and some combination of air or water takes warmth from one medium, carries that warmth away, and then vents excess heat safely into the atmosphere.

In order to perform this cyclic function, chillers need to keep refrigerant securely sealed in pipes and mechanisms designed to withstand heat and pressure. Special refrigerant liquids such as Freon make this process more efficient because they have boiling temperatures lower than boiling water temperature combined with freezing temperatures above freezing water temperature. This narrow range allows for much more efficient chemical reactions leading to faster removal of heat from air or water.

Parts of a Chiller

Although chiller designs differ in many ways, all chillers have certain key parts in common.

Chiller Condenser

The condenser takes heated refrigerant and swiftly cools it off in order to return it to a liquid state, starting the cooling cycle. Condensers can be air cooled, water cooled or evaporation cooled.

Compressor in a Chiller

At this stage, compression adds extreme pressure to the refrigerant liquid. This step sets the stage for the refrigerant to absorb heat. The type of compressor will vary by chiller. For example, screw chillers use twin rotary screws to achieve compression. Screw compression allows for high-speed continuous use with more even flow than other motorized compression types.

Chiller Evaporator

This part of the system cools liquid by taking highly-pressurized refrigerant as it cools. The chemical reaction results in extremely low temperatures which absorb heat from the liquid to be cooled.

Chiller Refrigerant

Refrigerant varies by chiller type, with some chillers including a mix of different chemicals. Because of environmental concerns, refrigerants of all types tend to be highly regulated. A given chiller must be rated to use with a certain refrigerant type in order to minimize refrigerant leakage. Over time, chiller service can include replacing or topping off refrigerants.

Expansion Valve of a Chiller

The expansion valve controls the flow of refrigerant into the system by sensing the actual and desired temperature. In industrial grade chillers, expansion valves can help create a chain reaction by adding more refrigerant as refrigerant starts to cool. As refrigerant goes through the standard chemical reactions, the valve pulls in more refrigerant to pull heat from refrigerant already released, creating even more rapid cooling.

Vents and Cooling Towers

All air conditioning requires venting of excess heat. Due to a high volume of liquid usually measured in tons, industrial chillers often require external cooling towers to control heat.

Chiller Images, Diagrams and Visual Concepts

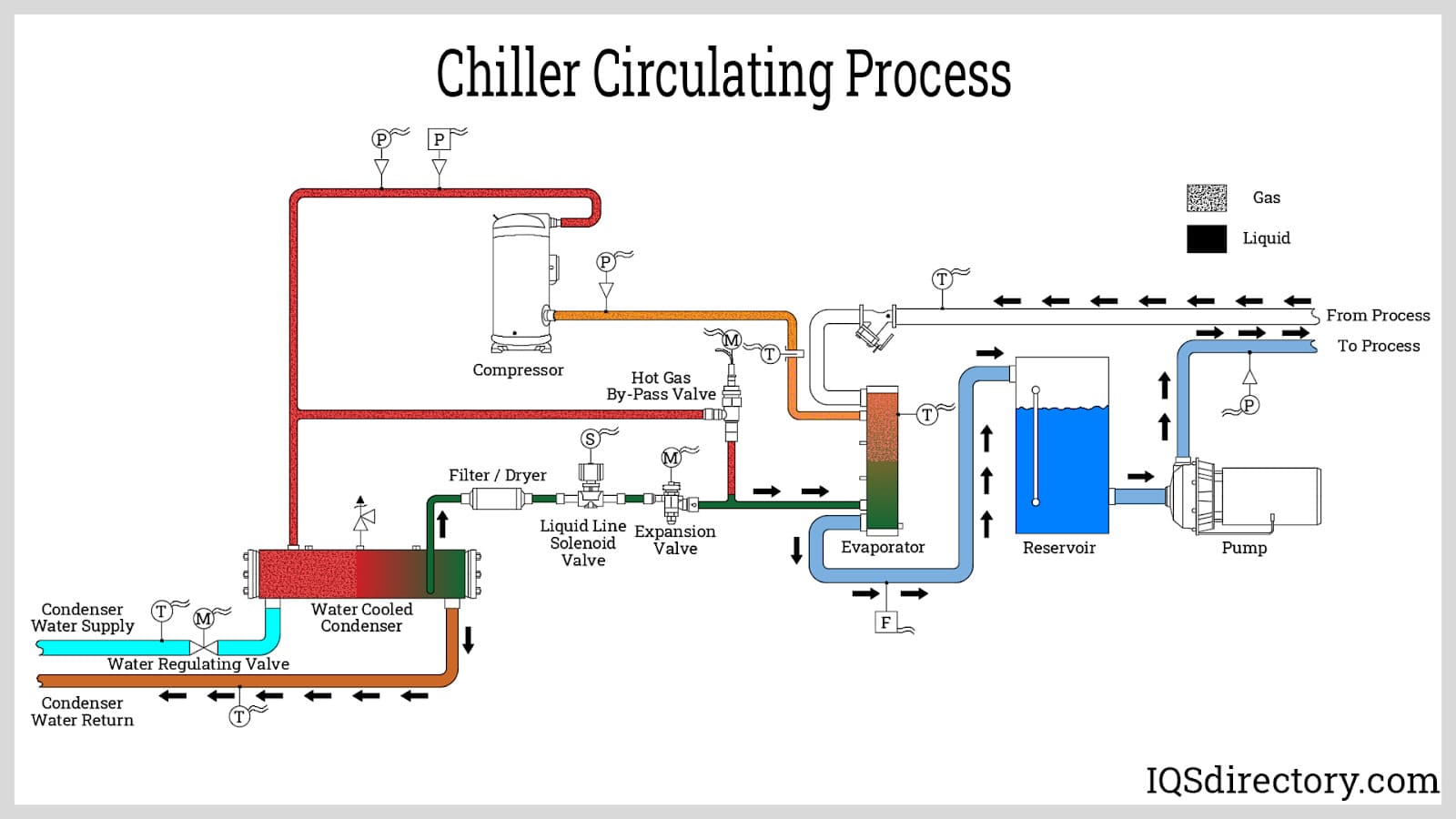

Chillers removes heat by circulating heat-absorbing a refrigerant through a series of mechanisms which releases the heat.

All chillers are designed to transform the refrigerant from a liquid to a vapor and back to a liquid, while in vapor form the refrigerant removes the heat from a process.

Industrial chillers circulates cooled liquid through equipment in order to maintain efficiency and productivity.

Glycol chiller uses a percentage of glycol mixed with water to create extremely low temperatures.

Laser coolers uses a multi-process that includes techniques in which atomic and molecular samples are cooled down to near absolute zero.

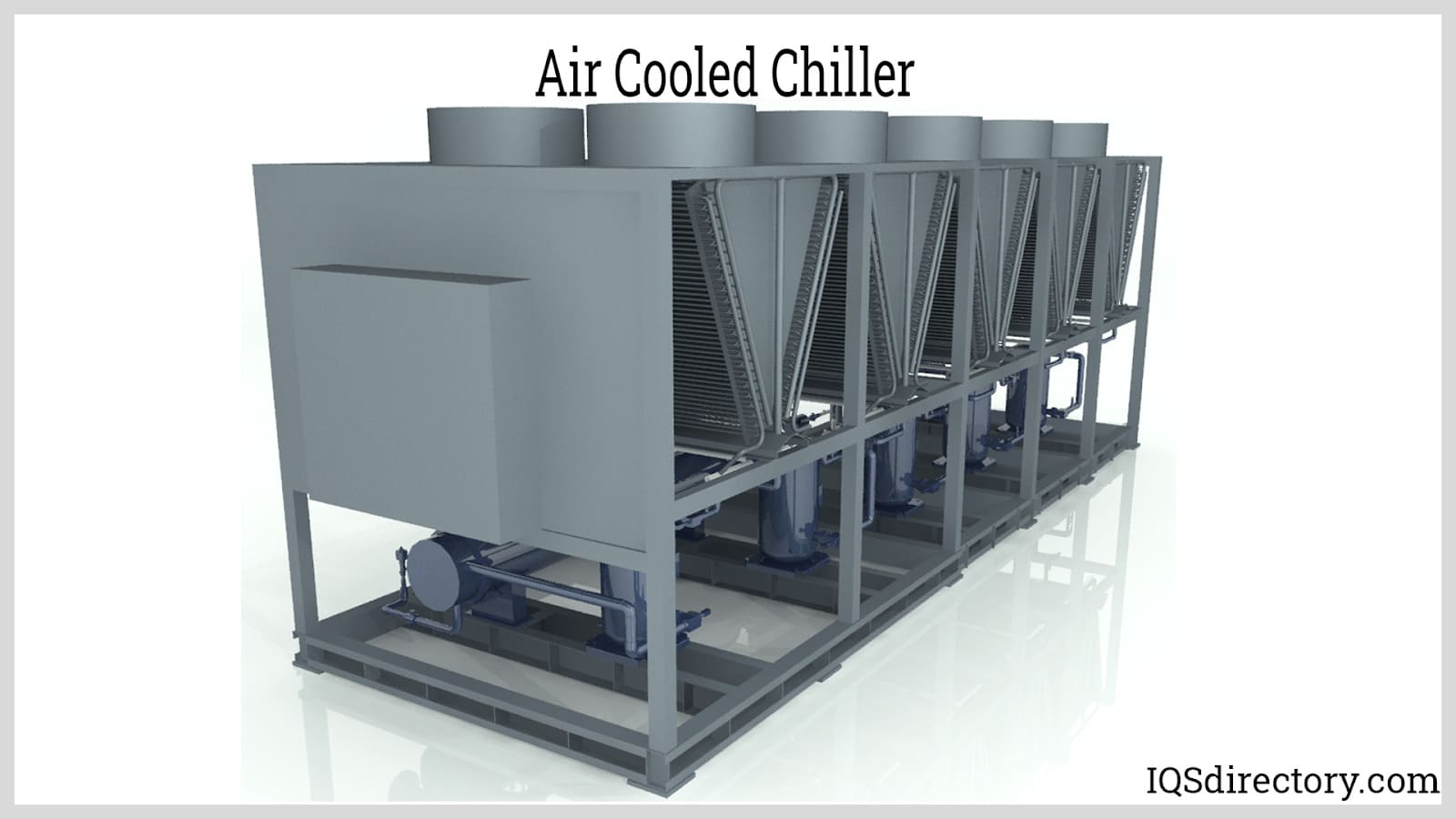

Air cooled chillers uses cool fluids that works in tandem with the air handler system and rely on fans to reject outside heat rather than relying on cooling towers.

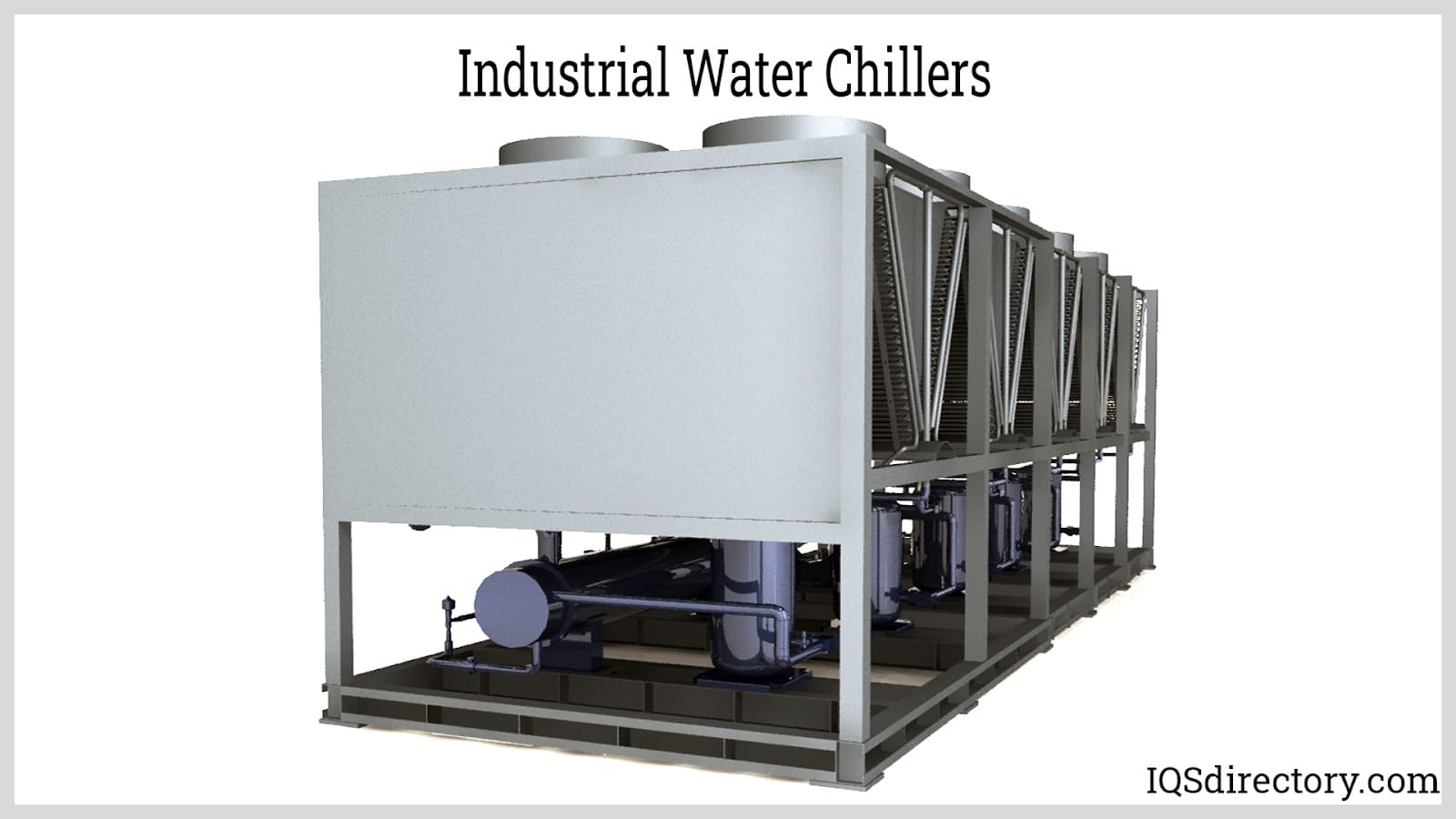

Water chillers uses water as a secondary refrigerant.

Centrifugal chiller uses compression to convert kinetic energy into static energy to increase the refrigerant pressure and temperature.

Chiller Types

Absorption Chillers

Chillers that use heat from combustion or hot water in place of electricity. Although absorption chillers use the same basic cycle of evaporator, compressor, condenser, the compression process uses a chemical solution instead of mechanical compression. At the compressor stage, chilled water enters the system to absorb heat in a heat exchanger. Refrigerant is diluted using a chemical solution and passed through the heat exchanger before proceeding on to the next stage in the cycle. The cold water then exits the system. Heated water or combustible material like gasoline then enters the system generator at the condenser stage. Industrial chillers of this type often need large cooling towers in order to hold water.

Air Cooled Chillers

Chillers that use ambient air to facilitate the condensation of the refrigerant during the condensing phase of the refrigeration cycle. They are the most common chiller type of chiller.

Blast Chillers

Used to preserve food by freezing it, and it is commonly used in the catering business. To blast chill food, a blast chiller is required. This is similar to a refrigerator, but because of its rapid chilling abilities it is much more expensive to manufacture and is usually only used in commercial kitchens.

Brewery Chillers

Typically are used in the cold crashing and fermentation of beer, and they usually circulate 28°F degree glycol for 33°F degree beer.

Central Chilled Water Units

Consist of air handling units fitted with chilled water coils and are utilized in air condition systems.

Centrifugal Chillers

A type of vapor-compression chiller that uses a centrifugal compressor to drive the refrigeration cycle.

Chiller Systems

Integrate a number of pieces of equipment in order to provide cooling for industrial processes or facilities.

Cooling Systems

Used to remove heat from an area.

Dedicated-Process Chillers

Operate year-round and are designed to provide specific, capacity-matched cooling protection and proper temperature/water flow. Dedicated-process chillers are the best choice for medical applications.

Evaporative Cooled Chillers

Uncommon but highly efficient liquid chillers. Evaporative chillers maintain the lowest condensing temperatures, which range from 85° F to 105° F.

Fluid Chillers

Provide process cooling using a secondary fluid.

Glycol Chillers

Refrigeration systems which circulate an antifreeze and water solution to help cool a variety of equipment and processes. These chillers use an antifreeze called glycol from which they receive their name. Since glycol is a food grade antifreeze, these types of chillers are most frequently used in the food and beverage industry.

HVAC Chillers

Often installed outside and are available in centralized and modular designs. HVAC chillers are used in industrial and commercial environments.

Industrial Chillers

Refrigeration systems that are used to chill various liquids in industrial settings.

Lab Chillers

A specific type of chiller used in laboratories to keep systems and sensitive matter cool. There are various types of lab chillers, as there are many laboratory applications for which chillers are required.

Liquid Chillers

Refrigeration systems that remove heat from various liquids.

Laser Chillers

Used to remove the heat generated from the heating of different components in a system.

Liquid Coolers

Typically recirculating chiller systems which recycle the same refrigerant liquid within a closed loop.

Machine Tool Chillers

Lower the temperature of coolant that is used in the cutting zone and recirculate it back to the machine tool in a closed-loop system.

Medical Chillers

Self-contained chillers with higher pressure pumping, temperature stability and microprocessor controls.

Portable Chillers

Self-contained units and are useful in small and/or dedicated applications.

Process Chillers

Chillers specifically designed to cool materials and machines during manufacturing and other industrial and laboratory processes, as opposed to HVAC chillers that are specifically designed for air conditioning. This chiller type refers to the amount of work these industrial chillers perform, and they are generally of the absorption type. Process chillers usually require substantial space, because they allow tons of refrigerant to cycle through at any given time. These chillers have the familiar cycle of evaporator, compressor, and condenser together with a metering device to control refrigerant levels. However, these parts are almost always high-quality stainless steel. In order to process tons of refrigerant at a time, industrial-grade evaporators, compressors, and condensers must be able to stand up to high pressures.

Recirculating Chillers

Constantly circulate coolant in a closed loop, retaining high efficiency without wasting water.

Screw Chillers

A type of vapor-compression chiller that uses a rotary screw compressor to drive the refrigeration cycle.

Water Chillers

Consist of a compressor, condenser and chiller with internal piping and controls all contained within a single unit. The term “water chillers” also refers to an overall package that includes a refrigeration plant, water chiller and air or water cooled condenser. While following the familiar cycle of evaporator, compressor, and condenser, these chillers cool water instead of air, pumping water out into an external system of pipes. These systems need to be carefully tailored to fit inside of existing structures.

Vapor Compressors

Follow a more conventional approach. Vapor compressor refers to the use of a standard mechanical compressor to vaporize liquid refrigerant for cooling purposes. High volumes of refrigerant move from the evaporator to the compressor and condenser. For smaller operations or where storing tons of coolant would not be practical, vapor compressors allow for quick cooling of large amounts of material.

Industry Uses for Chillers

When it comes to making the most of a chiller, this tends to depend on the individual industry. For example, manufacturing facilities continue to have the foremost need for this technology, using process chillers to keep machinery cool. In order to make use of process chillers, owners need to take a number of factors into account. First, they need the right chiller for the factory floor, given space and power supply options. Then, they need to look at the manufacturing schedule. This will shape how and when they use the chiller. As a general rule, chillers remain on only when needed. In some uses, for example water chillers used to supply water for a building, this may mean finding a chiller that can stay on constantly.

Many industries use chillers for their daily operations. Here are a few of the key industries which rely on chillers to work efficiently, safely, and effectively.

Uses in Manufacturing

The manufacturing industry, especially plastics, use industrial grade process chillers to remove heat from processed materials. Without chillers, many forms of production would need to grind to a halt for air cooling.

Uses in Food and Beverage

Federal law sets strict guidelines for any product intended for human consumption. Secure chillers provide even, reliable cooling systems for products and ingredients which need to be kept cold. Process chillers can flash-freeze tons of product at a time by surrounding products with sudden cold, without affecting moisture or ingredients.

Power Generation Industry Uses

The modern world would not be possible without power plants generating electricity for towns and cities around the world. The power supply industry uses process chillers to reduce heat caused by power generation. Without chillers, power plants would not be able to supply the amount of power they do using the amount of space they have.

Chillers in Medicine

Medical equipment and supplies sometimes need low temperatures in order to function. MRI machines and other large medical equipment generate large amounts of heat while they scan patients, and process chillers help to keep these machines from overloading. Liquid chillers are also used for storing medical supplies at low temperatures.

How to Custom Design Chillers

There are always some aspects of chiller technology unique to individual business requirements. As with any large equipment, space considerations will be a major concern. If machinery hooks up to pipes in order to keep water cool or regulate temperature in a room, then design requirements will need to consider the system as a whole. Volume of coolant, power source, size of the chiller as well as compressor and evaporator types can all be customized to fit individuals needs.

When designing a custom chiller, business should always plan for the future. Smaller, modular liquid chillers let owners move systems as needed, adding additional parts as business grows or changes. Larger, stationary models provide plenty of cooling power that can turn on and off as needed. The ideal custom system will mean considering all options in terms of the needs of the present and the possibilities for years to come.

Standards and Specifications for Safety With Chillers

In many cases, local and federal laws regulate the use of chilling technology. Food, beverages, and medicine must be kept safe for human consumption. Uneven cooling can result in contamination and product loss in many different industries, including plastic manufacturing. In addition to these concerns, refrigerant leakage can lead to health and environmental dangers. For this reason, government regulations usually limit chiller service and maintenance to licensed professionals with equipment designed to safely and securely handle liquid refrigerant.

When installing a chiller system, there are a number of important considerations. Foremost is cooling capacity. Industrial chillers are measured by their cooling capacity in terms of tons, each ton being roughly equivalent to the heat of fusion of one ton of ice, or 12,000 Btu/h. Capacities range from portable chillers with fractions of a ton to permanent multi-unit “plants” with cooling capacities of thousands of tons. Another significant decision is the sort of refrigerant; this will mostly depend on the range of temperatures the chiller will face. Common refrigerant choices include water, ammonia, carbon dioxide, sulfur dioxide, alcohol, brine and methane. Fluorocarbons, especially chlorofluorocarbons (CFCs) have also been used widely as refrigerants, but they are less common because of their ozone depletion effects. Other specifications to look at include condenser and evaporator flow rates, power source, cooling capacity, efficiency, location, compressor type and compressor horsepower. Most chillers also come with a local and/or remote control panel with temperature and pressure indicators and emergency alarms. When configured properly, chillers can provide simple and effective solutions for many process cooling and industrial air conditioning applications.

Things to Consider When Purchasing a Chiller

Chiller Expense and Your Bottom Line

One of the biggest expenses in any factory or manufacturing capacity is the expense of a chiller. Keeping things cool is expensive and requires a high level of energy. New innovations are made every year in the technology and energy-efficiency of chilling equipment on the consumer and industrial level.

But did you know how much more cost-effective new chillers are than old chillers? One company in San Francisco was able to save over $1.3 million dollars each year once they switched to a new chilling system. This company switched out old absorption chillers for new energy-efficient electric chillers. The company also upgraded the chilled water distribution system. The addition of the new system also saved over $100,000 in maintenance costs each year and the company was able to recover the cost of the system in fewer than 6 years.

Generally, when a company upgrades their chilling system, it is done out of necessity and the goal is to save as much during installation as possible. However, a shortsighted view like that can actually cost a company big money in the long run. By considering the long-term, this company was able to take funds traditionally spent on their utilities and use them for upgrades in other aspects of the business to increase profits. One simple move of upgrading the chiller system enabled the company to benefit as a whole on multiple levels.

The idea of spending money now to save money later is not a new idea, but few companies actually implement this idea. However, as the San Francisco company shows, upgrading one system can actually have a positive impact on the company as a whole and increase profits permanently.

Finding the Right Chiller Manufacturer

We have provided a convenient list of exceptional chiller manufacturers at the top of this page. The right manufacturer will depend on several factors, most of them unique to each individual business.

The right manufacturer should have proven ability and expertise in temperature control. An industrial chiller is a long-term investment, and the manufacturing business partner should match. In most cases, this includes certification to handle industrial-grade refrigerants.

Industry Knowledge

As a key part of overall business operations, chiller manufacturers need to be aware of overall business goals and requirements. This includes being aware of requirements specific to key industries, such as medical research.

Working Relationship With a Chiller Manufacturer

As with any long-term supplier of important goods, chiller manufacturers take time to understand business partners' unique requirements in order to provide helpful advice regarding custom options. In order to do so, they must carefully cultivate firm working relationships built on mutual respect.

Chiller Terms

Ambient

The surrounding environment, including temperature, pressure and/or humidity, coming into contact with a system or component.

Brine

Mineralized water consisting of sodium chloride, metallic and/or organic contaminants.

British Thermal Units (BTU)

A measurement unit reflecting the amount of heat needed to change the temperature of one pound of water one degree Fahrenheit.

Capillary Tube

Tube located between the condenser and evaporator that manages the refrigerant flow.

Central Chilling System

A chilling system that is self-contained. A central chilling system has more than one unit and more than one compressor but no pump tank set.

Chlorofluorocarbon (CFC)

A gas consisting of chlorine, fluorine and carbon that has been used as a refrigerant in such items as liquid chillers. CFCs cause ozone depletion, because they do not break down upon release into the atmosphere, but mix with ultraviolet light to create carbon dioxide, and eventually ozone-eating chlorine radicals.

Coefficient of Performance (COP)

The measurement of a refrigeration system’s efficiency that compares the system’s cooling ability with the heat input necessary to attain such cooling. COP is calculated by dividing a system’s cooling ability by the system’s heat input and is expressed in BTU/hr.

Compressor

A device that increases pressure on a gas through the act of pumping. Compressors are responsible for the compaction of the vaporized refrigerant to a pressure level suitable for liquefaction, which occurs in the condenser.

Condenser

A device that removes heat via forced air, water coil, etc., in order to convert a high pressure gas into a lower pressure liquid. Condensers remove heat from the compressed vaporized refrigerant, at which point, the refrigerant returns to a liquid state.

Control Center

The central part of a refrigeration system in which the system is operated and maintained.

Coolant

A liquid used to remove heat.

Energy Efficiency Rating (EER)

Indicates the efficiency of an air conditioner or cooling system by comparing the amount of energy needed to produce cooling with the quality of the system’s cooling ability and is calculated by dividing the system’s BTU by its wattage. For example, if a cooling system maintains 20,000 BTUs and uses 1,500 watts, the system’s energy efficient rating would equal 13.3.

Evaporator

Consists of a tube inside which the refrigerant soaks up heat from it surroundings, boils and changes to a vapor.

Expansion Valve

Mechanism located between the evaporator and condenser that controls the refrigerant flow into the evaporator and controls the temperature of the evaporator.

Filter Drier

Removes moisture and contaminants from vaporized refrigerants.

Heat Exchanger

A device that transfers heat from one fluid to another without mixing the fluids.

Hydrochlorofluorocarbon (HCFC)

A substance containing chlorine, fluorine, carbon and hydrogen that is used as an alternative to CFCs as a refrigerant and a propellant. HCFCs produce fewer effects on the ozone layer than CFCs do.

Hydrofluorocarbon (HFC)

A substance containing hydrogen, fluorine and carbon that is used to replace CFCs and HCFCs because of HFCs lack of effect on the ozone layer. HFCs produce no ozone depletion because the substance does not contain chlorine, which breaks down the ozone layer.

Laser Cooling

A process that utilizes light to cool atoms to a very low temperature.

Ozone

A molecule containing three oxygen atoms that absorbs ultraviolet radiation in the stratosphere. Ozone also remains a harmful component of smog and can contribute to lung damage and respiratory problems.

Ozone Depletion Potential (ODP)

A relative measurement of a substance’s negative effect on the ozone layer as compared to the effects of CFC-11, which has an ODP of 1, on the ozone. For instance, a substance with an ODP of 2 can potentially cause approximately twice the ozone depletion as CFC-11 could.

Ozone Layer

Also referred to as the stratospheric ozone, it is the protective atmospheric layer in the stratosphere, located 12-30 miles (20-50 kilometers) above sea level, in which ultraviolet radiation is absorbed.

Receiver

The storage area for condensed liquid refrigerants.

Refrigerants

Liquids that produce cooling upon evaporation.

Refrigeration Ton

Unit equal to 12,000 BTUs that refers to the size of the chiller unit.

Sight Glass

A window in a refrigeration system through which specialists can view the inner workings of the system.

Solenoid Valve

Mechanism in a refrigeration system that controls the flow of refrigerant, especially into the expansion valve.

Total Equivalent Warming Impact (TEWI)

The total amount of carbon dioxide that a refrigeration system can produce throughout its lifetime.

Chiller Informational Video